Organizations are constantly seeking ways to improve operational efficiency and reduce costs. This is particularly the case in manufacturing where many companies are finally rebounding from supply chain issues as a result of the global pandemic. In the search for solutions, leadership has relied upon insights generated from operational data, field input and the voice of customer. And while these sources are without doubt valuable, they may not reveal with clarity the real and monetizable opportunities for the enterprise.

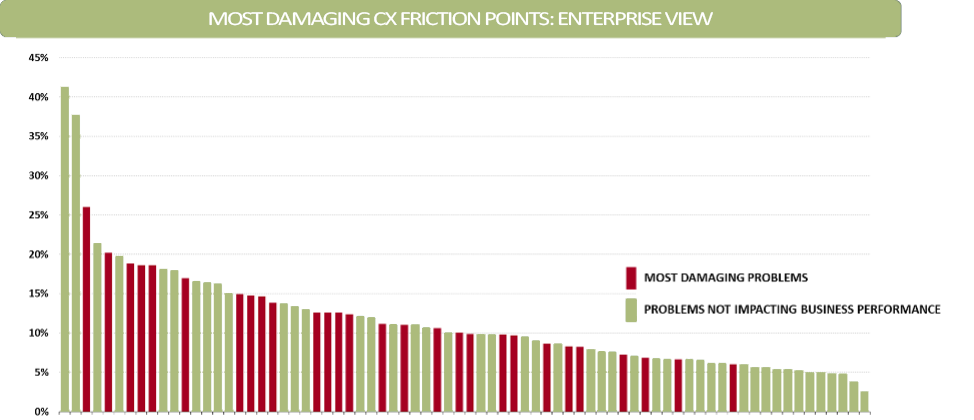

For over 20 years, the Verde Group has worked with manufacturers and other industry leaders to uncover the highly predictive drivers of customer behavior—CX friction. Understanding CX friction within the operational and relationship dynamics of a business is not new. However, what is new and innovative is separating the noise from signal. And there is a lot of noise out there. In most, if not all cases, frequent issues described by sales and service leadership, front line staff, and even customers themselves, are not the issues representing market risk and growth opportunities. This is proven in the example below. This leading manufacturer of medical technology realized that the issues they were trying to address simply did not represent the true economic and strategic opportunities to improve the manufacturer’s business performance.

2022 Verde Group Manufacturing Client

It is a fact that if executed properly, CX insights can and should inform strategic investments and tactical initiatives. The challenge is that many CX insight efforts seek to understand customers’ attitudes toward their product, service, and brand. The “how much you love us” surveys and analytical methods, while interesting, simply won’t get it done. Attitudes are merely a cognitive expression of a customer’s experiences. So why not focus on understanding which specific experiences shape a customer’s attitudes and more importantly, drive their behaviors? Here’s three reasons why focusing on experiences (not attitudes) will help your CX insight program improve operational efficiency and overall business performance:

- Specific experiences are observable—either they happened, or they didn’t.

- Negative experiences (CX friction points) are much more predictive of negative market action because a customer is 10x more likely to act on a negatively stated intention.

- With this information, the likelihood of your company taking action increases.

By strategically and economically prioritizing specific CX friction points, companies have a roadmap to guide investments in people, process, and technology platforms.

The Link Between CX and Operational Efficiency

Customer experience (CX) has emerged as a critical component of business strategy across various industries, including manufacturing. A study by Deloitte revealed that companies with a customer-centric approach are 60% more profitable than those that do not. This profitability often stems from operational efficiencies gained by addressing customer pain points.

Identifying Pain Points in Manufacturing

Manufacturing industries face unique challenges when it comes to CX insights. The complexity of their customer relationships requires an approach that cuts through the noise and zeroes in on what matters most to the business. For example, common pain points can include experiences such as a lack of a single point of contact, complexity in the ordering processes, lack of ongoing business support and proactive communications regarding the status of issue resolution. Each of these issues can lead to customer dissatisfaction and increased operational costs.

Case in point, a manufacturing company was experiencing frequent delays in product delivery, causing customer frustration and putting their business relationship at risk. But this was not the whole story. By analyzing customer feedback and prioritizing specific CX drivers of this issue, the company could act by implement targeted improvements, such as proactive communications that managed customers’ expectations, streamlining inventory management processes via improved supplier relationships and acknowledging delays by “making things right”. These efforts not only strengthened the overall relationship with the customer but resolved pain point by streamlining internal processes and reducing operational costs.

Streamlining Processes

Addressing pain points often involves streamlining processes to eliminate inefficiencies. For instance, automating repetitive tasks and integrating advanced technologies can significantly improve production workflows. As mentioned in a recent Forbes article, manufacturers that embrace Industry 4.0 technologies, such as IoT and AI, can reduce operational costs by up to 20%.

Consider the case of a manufacturer that receives frequent complaints about the complexity of its ordering process. By investing in an intuitive, user-friendly online ordering system, the company can simplify the process for customers, reducing errors and order processing time. This enhancement not only improves the customer experience but also allows the company to reallocate resources more efficiently, resulting in cost savings.

Reducing Costs through Proactive Issue Resolution

Proactively identifying and resolving customer pain points can prevent costly issues from escalating. A study by Accenture found that poor customer service can lead to a 15% increase in operational costs due to the need for problem resolution and service recovery. By addressing pain points before they become major issues, manufacturers can avoid these additional costs and focus on long-term manufacturing efficiencies.

For example, a manufacturing company that receives consistent feedback about product defects can implement a robust quality control program. This proactive approach not only improves product quality but also reduces the need for costly returns and replacements. As a result, the company can allocate resources more effectively and improve overall operational efficiency.

Real-World Success Stories

Several manufacturing companies have successfully improved operational efficiency by addressing customer pain points. For instance, General Electric (GE) implemented a comprehensive customer feedback system to identify areas for improvement in its manufacturing processes. By addressing issues such as product reliability and delivery times, GE was able to enhance customer satisfaction and achieve significant cost savings.

Another example is Toyota, which adopted the Toyota Production System (TPS) to streamline its manufacturing processes. TPS focuses on continuous improvement and waste reduction, leading to improved operational efficiency and higher customer satisfaction. By addressing pain points such as production delays and inventory management, Toyota has become a global leader in manufacturing excellence.

The Verde Group recently worked with a leader in the manufacture and sale of agricultural, construction, and powertrain equipment. The client wanted to know what actions they should take to improve the customer experience and deliver the largest shift in customer loyalty. With our innovative Revenue@Risk® analysis, the company learned that equipment operation was a shared problem area for both customer and dealer. The client implemented more stringent QC standards during the engineering and manufacturing stages, which resulted in improved customer satisfaction.

Conclusion

Addressing pain points in the customer experience is a powerful strategy for improving operational efficiency in the manufacturing industry. By identifying and resolving these issues, manufacturers can streamline processes, reduce costs, and enhance overall business performance. As the competitive landscape continues to evolve, prioritizing CX will be essential for manufacturers looking to achieve long-term success.

—

For more information on how Verde Group can help your manufacturing business improve operational efficiency through pain point resolution, contact us.